Nano-Sized Dust Risks from 3D Printing: Dacian Brings Clean Air to Printing Workers

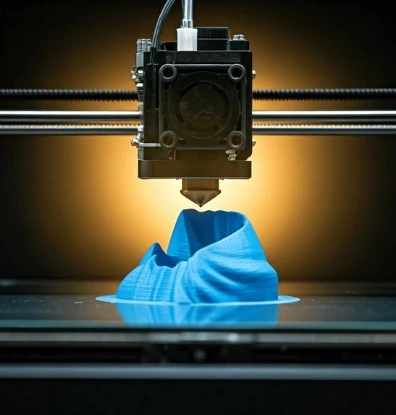

As 3D printing technology becomes widely adopted in mold design and manufacturing, many factories benefit from improved efficiency and flexible design options. However, the hidden risks to respiratory health are often overlooked.

Taiwan-based professional respiratory protection brand Dacian Mask warns that the 3D printing process releases large amounts of nano-sized dust. These invisible particles, when inhaled over time, can silently damage the lungs. Protecting your breath shouldn’t wait until symptoms appear—every worker quietly dedicated to the production floor deserves care.

Dust is continuously released during material layering, powder removal, and sanding. The greatest risk occurs the moment the protective cover is lifted after printing, when a surge of high-concentration nano particles bursts into the air. Operators closest to the machine inhale these particles directly. The air we breathe at that moment is essentially the same as what the exhaust hood draws in—filled with unseen pollutants.

Nano-sized dust is colorless and odorless but can penetrate deep into the alveoli and remain trapped inside the lungs, potentially causing chronic inflammation and respiratory diseases over time. “The biggest risks are often the ones you can’t see or smell,” a Dacian Mask representative explains. “Many think turning on an exhaust fan or air purifier solves the problem, but ultrafine particles can stay suspended in the air for long periods, silently entering our lungs with every breath.”

For this reason, Dacian emphasizes that relying solely on air conditioning or machine filtration is not enough to protect workers in 3D printing environments. True protection comes from masks designed for long-term wear that effectively block nano particles.

To meet this need, Dacian developed the Nanofaser Filtermaske, combining high-efficiency nano membranes with electrostatic filter materials. It filters fine particulate matter, resin powder, and metal dust while addressing the heat and long working hours typical of production sites with a breathable, comfortable, washable, and reusable design.

“Factories can be highly advanced and automated, but employee health shouldn’t be left to chance. Respiratory health isn’t a luxury—it’s a basic necessity that must be protected every day.”

Dacian sincerely invites manufacturers, factory managers, and everyone who cares about workplace safety to recognize the invisible risks of 3D printing dust and work together to build truly safe, healthy, and trustworthy work environments.